Evergrande will build electric cars on a large scale

Last year, Evergrande New Energy Automobile Group signed strategic agreements with well-known names in the automotive industry. These include the German automotive engineering company FEV Group, EDAG, IAV Group as well as AVL from Austria and Magna from Canada. Among others, the well-known Italian design office Pininfarina is involved in the design of the new electric vehicles that are to debut under the Hengchi brand. The previous partners of Evergrande’s automotive subsidiary are also of interest: with the German manufacturer Hofer, they are developing drive trains for electric vehicles, Evergrande has acquired a license from the supplier Benteler for their “Electric Drive Systems” module, and in 2019, the Evergrande Group took over 51 percent of the shares from NEVS (National Electric Vehicles Sweden). NEVS, in turn, bought the insolvent Swedish car manufacturer Saab in 2012, including the plants, patents and their technology.

Evergrande has also already launched electric vehicles on the Chinese market. In June 2019, NEVS presented the NEVS 9-3, a pure electric car based on the Swedish Saab PhoniX-E platform and with further technology from Saab. Basically, NEVS had already completed the research and development of the 9-3 model before the acquisition of Evergrande, the vehicle is only marketed by Evergrande. Previously, Evergrande had already produced electric cars in small series, the NEVS 9-3 is the first model to be mass-produced. Through shareholdings, takeovers and agreements with manufacturers of vehicle parts, batteries, drive trains and charging stations, Evergrande has become a fully fledged car manufacturer. They have announced to invest 280 billion yuan (40 billion US dollars) in the construction of two plants in Nansha and Shenyang for the production of electric cars. The first electric car developed by Evergrande themselves, Hengchi 1, is to be presented in the first half of 2020 and series production is to start in 2021.

Under the new agreement with its automotive partners, Evergrande plans to develop 15 new luxury and mid-range models. The ambitious goal of the real estate group is to become the world’s largest electric car company within the next three to five years and to produce and sell around five million vehicles within the next ten years. For this project, 8,000 additional experts and specialists are to be hired in addition to the existing workforce. Xu Jiayin, Evergrande Group’s CEO, is confident that China will soon become a world leader in alternative drive vehicles. Your company is active in the automotive or electronics sector and you would like to export your products to China or produce locally? Then in most cases you will need a so-called CCC certificate. The CCC (China Compulsory Certificate) corresponds to the European CE system and is used for product safety and standardization of product quality. We will be happy to advise you on the certification process and carry it out for you.

For more information on how CCC certification, the CCC Self-Declaration and voluntary CCAP or CQC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

Here you can download our brochure about the CCC Self-Declaration.

Here you can download our brochure about the voluntary CCAP or CQC certification.

CCC Certification for Explosion Protection Products in China

With the announcement of the Chinese market regulation authority SAMR (State Administration for Market Regulation), a CCC certification is mandatory for many explosion protection products starting October 1, 2020. This means that a valid CCC-Ex certificate must be received for these products by October 1, 2020 at the latest, otherwise these products may no longer be imported to China. Up until now the explosion proof (“Ex”) products were excluded from the CCC obligation.

With the announcement, the authority also published the new implementation rules CNCA-C23-01: 2019 in which it regulates which products have to be CCC certified in the future:

CNCA-C23-01:2019:

- Explosion-proof motor

- Explosion-proof electric pump

- Explosion protection distribution systems

- Explosion-proof switches, control and protection products

- Explosion-proof starter products

- Explosion-proof transformer products

- Explosion-proof electrical drives and solenoid valves

- Explosion-proof connector

- Explosion-proof surveillance products

- Explosion-proof air conditioning and ventilation systems

- Anti-explosion communication, signaling device

- Explosion-proof electrical heating products

- Explosion-proof accessories, Ex components

- Explosion-proof instrumentation products

- Explosion-proof sensors

- Safety barrier products

- Explosion-proof instrument housing

Electronic products must be tested according to their Ex type. The GB standards regulate the necessary tests. Explosion-proof products can be tested for one or more Ex types.

According to the implementation rule CNCA-C23-01: 2019 the following tests result:

| No. | Explosion-proofing type | Criteria | |

| General Standards | Detailed Standards | ||

| 1 | Explosion suppression “d” | GB3836.1 | GB3836.2 |

| 2 | Increased safety “e” | GB3836.3 | |

| 3 | Intrinsically safe “i” | GB3836.4 | |

| 4 | Positive pressure enclosure “p” | GB/T3836.5 | |

| 5 | Immersion “o” | GB/T3836.6 | |

| 6 | Sand filling “q” | GB/T3836.7 | |

| 7 | “n” type | GB3836.8 | |

| 8 | Encapsulation “m” | GB3836.9 | |

| 9 | Intrinsically safe “iD” | GB12476.1

|

GB12476.4 |

| 10 | Enclosure protection “tD” | GB12476.5 | |

| 11 | Encapsulation protection “mD” | GB12476.6 | |

| 12 | Positive pressure protection “pD” | GB12476.7 | |

If your company already has NEPSI (SITIIAS) certificates or IECEx test reports / certificates, product tests may be avoided or reduced. After a thorough examination of your documents (certificates, test reports, etc.), the Chinese authorities will decide whether further tests are necessary for the initial approval of your products.

Manufacturers of affected products from the explosion protection area are encouraged to start the certification process as soon as possible in order to have the CCC-Ex certificates available in time for the October 1, 2020 deadline.

Are you already active in the Chinese market and want to learn more about how the new regulations effect on your business? Do you want to start exporting your products to China? Please do not hesitate to contact us, we are happy to advise you on the new regulations in detail and make recommendations that suit your individual needs. We also offer original Chinese versions of the Chinese regulations as well as English translations.

For more information on how CCC certification, the CCC Self-Declaration and voluntary CCAP or CQC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

Here you can download our brochure about the CCC Self-Declaration.

Here you can download our brochure about the voluntary CCAP or CQC certification.

CQC certification for EV batteries as guarantee for product conformity as China Considers Extending Electric-Car Subsidies

The Chinese government is discussing the extension of subsidies for electric cars beyond next year to support sales in the world’s largest market. According to internal sources, decision-makers have already considered this possibility when annual sales of vehicles with alternative drive systems declined for the first time. The decline is the result of lower subsidies for buyers of electric cars since July 2019 to streamline the industry and make it less dependent on government support. Following the outbreak of the Coronavirus, further pressure is now being exerted on the Chinese auto industry, which is struggling with production interruptions and a lack of customers in the showrooms.

At present, discussions on the extension of subsidies are still at an early stage and it is not possible to say exactly how long the funds will be extended. If there is no result, the subsidies will expire at the end of 2020. Local manufacturers of electric cars such as BYD, BAIC BluePark New Energy Technology and NIO would benefit most from an extension of the subsidies. US manufacturer Tesla, which began delivering vehicles from its new plant in Shanghai last month, would also benefit from the subsidies. Sales of vehicles with alternative drive systems, i.e. electric cars, plug-in hybrids and fuel cells, fell by 54 percent in January 2020 compared to the previous year. According to the Chinese Automobile Manufacturers Association, the decline affected the entire automobile market and not just electric vehicles. These figures were calculated before the corona virus outbreak and led to plant closures and production breaks.

After the extent of the coronavirus epidemic became known, the nationwide car industry in China practically came to a standstill. Sales figures in the first two weeks of February plummeted by 92 percent, the Association of Automobile Manufacturers reported. Nevertheless, it is likely that the numbers will recover after the health crisis is overcome. China introduced subsidies for electric cars ten years ago and these have since played a significant role in developing the country into the world’s most important market. The government then published a timetable four years ago that provided for the subsidies to be phased out by the end of this year. At the same time, a points system was set up that obliges all car manufacturers, local and foreign, to produce at least some electric vehicles. For traction batteries of electric cars, but also other batteries and accumulators, there is the possibility to have them voluntarily certified by the CQC. The CQC seal of approval stands for China Quality Certificate and is issued by the same authority as the obligatory CCC certificate. We will be happy to advise you on which products require the appropriate certification and will carry out the certification process for you.

For more information on how CCC certification, the CCC Self-Declaration and voluntary CCAP or CQC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

Here you can download our brochure about the CCC Self-Declaration.

Here you can download our brochure about the voluntary CCAP or CQC certification.

China promotes technology for swapping vehicle batteries at charging stations

With plans to introduce a technology for rapid battery swapping as well as uniform standards for batteries, China is on the advance to establish electric vehicles in what is currently the largest global market for new vehicles. The government is working on uniform standards for the automotive industry to enable drivers of electric vehicles to quickly replace their empty batteries. Currently, even with rapid charging stations, a charging process takes at least several hours. The aim of a uniform standard is to replace the batteries at every charging station or petrol station, regardless of the vehicle manufacturer.

These efforts once again show China’s advantages over other nations in the introduction of new technologies, a country where the government has influence over entire branches of industry. For example, China has sold about half of all electric vehicles produced worldwide. Nevertheless, there was a slight decline in July 2019 when subsidies for buyers were cut. The country’s long-term goal remains to phase out internal combustion engines. A replacement system for vehicle batteries would not only save time for drivers. It could also reduce the price of electric vehicles and make them more competitive with conventional vehicles. The reduction in price is due to the fact that owners buy or rent the batteries separately. In return, the government is planning tax breaks to make the transition to an electric vehicle more attractive.

Vehicle manufacturer Tesla has already tested a corresponding battery swap service in the USA, but has not launched it on the market. Tesla began delivering electric vehicles from its new plant in Shanghai in December. It is the first production facility outside the USA and is expected to increase Tesla’s sales in China. The Chinese Ministry of Industry and Information Technology has confirmed plans to introduce battery replacement systems, but did not provide any further details. Electric vehicle manufacturers, BAIC BluePark New Energy Technology and NIO are already testing systems that take less than three minutes to change the battery. However, in the absence of uniform standards, only BAIC vehicles are currently able to change batteries at their own stations. To this end, BAIC BluePark has set up 187 charging stations in 15 Chinese cities for the approximately 16,000 electric taxis of the brand. Your company could also benefit from the introduction of this new technology in China. Products from the automotive and electrical industries require CCC certification for export to China. We would be happy to advise you on certification according to the CCC (China Compulsory Certificate) guidelines.

For more information on how CCC certification, the CCC Self-Declaration and voluntary CCAP or CQC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

Here you can download our brochure about the CCC Self-Declaration.

Here you can download our brochure about the voluntary CCAP or CQC certification.

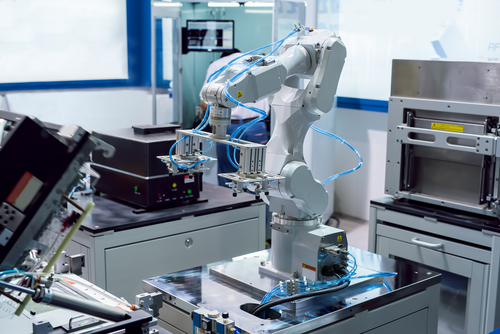

Korea Certification (KCs) for Industrial Robots becomes more important as market reaches new record of 300,000 industrial robots in operation

According to a report by the International Federation of Robotics (IFR), South Korea currently has around 300,000 industrial robots in use, an increase of 10 percent over the previous year. Within five years, the Asian country has doubled the number of industrial robots and is now in third place after Japan and China. Nevertheless, there has been a decline in the installation of robots in recent years and a slight decrease is expected for this year as well. The president of the IFR, Junji Tsuda, expects a worldwide decline in the installation of industrial robots of 5 percent to 37,807 units. Weaker demand from the electronics and automotive industries, which together account for 82 percent of all customers, is mainly responsible for the decline.

South Korea is also affected by the trade dispute between the USA and China. This has both positive and negative effects. China is an important export market for semi-finished products from South Korea, so there could be a decline in trade. On the other hand, Korean products could replace certain products from China in parts of the world. Nevertheless, the Korean economy is currently in difficult circumstances. Consumers are buying fewer electronic goods and announcements by leading companies that they are holding back investment suggest another year of declining robot installations.

The widespread use of industrial robots is inevitable for South Korea’s competitiveness. The population is aging rapidly and by 2050 it will have one of the oldest societies of any OECD country. This explains why South Korea already has the second highest number of robots in the world in the manufacturing sector. After Singapore, which leads the field, South Korea has 774 industrial robots per 10,000 workers. This is more than twice as many as in third-ranking Germany with 338 and Japan with 327 units. In 2019, the government of South Korea launched an education and training program to help employees operate robots and automated manufacturing equipment. By 2022, 50,000 factory workers are to be trained accordingly. Another funding program provides for the training of 2,200 employees of small and medium-sized enterprises to prepare them for the use of industrial robots. In South Korea, industrial robots require a self-regulating safety check according to the guidelines of the Korea Certification (KCs Mark, s stands for safety) for machine safety. The mark is issued by the Korean Occupational Safety and Health Authority (KOSHA). We advise your company and carry out both KC Certification and KCs Certification with our local partners.

Tesla designs compact vehicle for Chinese cities

Tesla plans to establish a research and development center in China to design and produce smaller vehicles. The focus is not only on the Chinese market, but could also supply other emerging markets with the new model. As is typical for Tesla, the corresponding announcement was not distributed via press agencies, but via the most widespread social media application in China, WeChat. Tesla CEO Elon Musk also announced that his company is planning to switch from “Made in China” to “Designed in China”. To this end, he called on the public to submit designs of future Tesla vehicles that are suitable for the Chinese market.

Meanwhile, the first Tesla Model 3s were delivered from the new gigafactory near Shanghai in December. It is likely that a smaller or more compact Tesla vehicle will also be produced in this factory. In first published pictures the new vehicle has some similarity to the Model 3 and would compete with compact electric vehicles like the Volkswagen ID.3. In addition to the planned compact vehicle, production of the compact SUV Model Y for the Shanghai factory has already been confirmed. Tesla stated that plans for this are at an advanced stage and that the company’s fourth model could be launched in mid-2020 instead of at the end of the year as planned.

To avoid tariffs and import duties on imported vehicles, Tesla has built its first gigafactory outside the USA in just 10 months. The Shanghai plant has an annual capacity of 500,000 vehicles. Tesla reported sales of 1.2 million vehicles last year for China, the world’s largest market for electric vehicles, which is also the largest market for its Model 3. Take advantage of your opportunities in the Chinese automotive market. Products for export to China often require CCC certification. We will be happy to advise you whether your products are covered by this regulation and carry out certification for you in accordance with the CCC (China Compulsory Certificate) guidelines.

For more information on how CCC certification, the CCC Self-Declaration and voluntary CCAP or CQC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly here on Amazon.

Here you can download our brochure about the CCC Self-Declaration.

Here you can download our brochure about the voluntary CCAP or CQC certification.

Electric Vehicles for the Chinese Market Make Battery Registrations More Important

The American automotive giant General Motors has unveiled an affordable electric vehicle, which will be exclusively sold in the Chinese market. The Chevrolet Menlo is intended to enable the company to enter the biggest market for electric vehicles. The sole focus on the Chinese market makes the homologation process easier, because only compliance to Chinese regulations needs to be ensured. For example, batteries for electric vehicles have to go through a battery registration process in China. Conformity with GB/T 34014 is meant to ensure the traceability of the battery system over the entire life cycle.

The Chevrolet Menlo builds on the platform of the Chevrolet Bolt and can be classified into the compact SUV segment. The electric motor provides power of 110 kW and 350 Nm and the battery capacity promises a mileage of about 400 kilometers on a single charge. Modern quick-charging technology will enable recharging the batteries to 80 percent in just 40 minutes. To adapt the handling to individual driving styles, drivers can choose from three different driving and recuperation modes.

A 10-inch touch display offers connectivity to the smartphone via different systems like Apple CarPlay and Baidu Car-Life. In addition, different driver assistance and safety systems like ABS, ESP, a lane-keeping and parking assistant, cruise control and a collision warning system are built in. The trunk will hold a volume of up to 1000 liters.

GM is expecting high sales figures fueled by the low entry price of 160,000 RMB (about 23,000 USD) after taking state subsidies for electric vehicles in China into consideration. For the launch the car will only be sold in the capital of Beijing, but sales are planned to be expanded to the whole country shortly after. It remains unclear whether GM is aiming to broaden sales of the Chevrolet Menlo to other countries.

If you also deliver battery systems to China and have questions around complying with the requirements of GT 34014-2017, you can contact us any time.

Call us directly at +49-69-2713769150 or send us an E-mail.

New technology for car headlights

Conventional car headlights consist of lamps and various optics to project a beam of light onto the road. The primary development goal is to improve safety in poor lighting conditions and adverse weather conditions. In LED headlamps, free-form lenses distribute the light precisely and with better light distribution than halogen or xenon (HID) lamps. The latest LEDs for the automotive sector are much brighter than conventional halogen lamps and as bright as a 35 Watt HID headlamp. LEDs consume less energy and have their full power immediately after switching on, unlike conventional lamps which require a certain amount of time to reach maximum power. In addition, the LED headlights are easier to repair and do not require a separate ballast for operation.

The latest development in vehicle LEDs is matrix LED systems. Drivers can already benefit from this technology today; the e-tron Sportback from Audi incorporates a so-called Digital Matrix Light. In the system from US technology group Texas Instruments, tiny mirrors, so-called digital micromirrors, divide the LED light into 1.2 million individual pixels. The result is an even brighter and better illuminated cone of light in front of the vehicle but with less glare for other road users. But the technology also has other functions: It can, for example, project improved dynamic curve light and reduce the amount of light when approaching oncoming vehicles in order to reduce glare or, with additional lines in the cone of light, to depict the dimensions of the vehicle on the road. This should be particularly advantageous in narrow traffic situations such as construction sites or winding country roads. The designers for future LED headlamps go one step further and test animated light shows to greet and say goodbye to the driver as well as a function that directs the light onto the adjacent lane when changing lanes.

The Mercedes Maybach already has the Digital Light for a certain time. Using software, symbols in HD quality are also projected onto the road and displayed with arrows in the danger zone near the roadway to indicate pedestrians or obstacles. If cruise control with distance control is activated, a mark with the set distance is displayed on the road. In addition, sensors and the networked on-board computer display hazards such as icy roads, construction sites and messages from the assistance systems on the road. LED headlights will certainly be standard equipment in the future. The Chinese automotive market is known for its innovation and rapid implementation of new technologies. Do you produce automotive components such as headlamps or other components? For export to China or local production, these products must undergo a mandatory CCC certification. We will be happy to advise you on the upcoming CCC (China Compulsory Certificate) of your products.

For more information on how CCC certification, the CCC Self-Declaration and voluntary CCAP or CQC certification may affect your company, or for more information about CCC certification in general, the process, and the associated costs, please visit our website and our News Section where you will find current updates twice a week.

Please do not hesitate to contact us for further details and consultation. You can contact us via e-mail, or call us (UK: +44 2071931135, Rest of Europe: +49 69 2713769150, US: +1 773 654-2673).

You can also check out our free CCC-Brochure, which can be downloaded right here as a PDF file or you consult our book (in English) “A Brief Guide to CCC: China Compulsory Certification”, which can be found directly hier on Amazon.

Here you can download our brochure about the CCC Self-Declaration.

Here you can download our brochure about the voluntary CCAP or CQC certification.

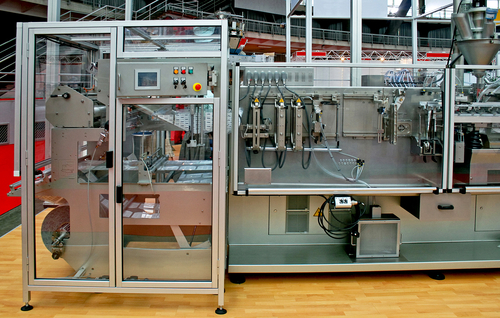

Pre-shipment Inspection Enables Increasing Demand of Imported Used Machines in China

With the “Made in China 2025” strategic plan from 2015, China is trying to upgrade its own economy. According to this plan 70% of the share of core materials should be manufactured directly in China by 2025. This mainly affects high-tech areas including the pharmaceutical industry, which has so far largely been dominated by foreign companies.

In order to achieve its goals China is predominantly asking for new machine and plant technologies. The trade in used machines has only recently started to play an increasing role. Previously, the import of used machines was not desired and was therefore associated with high administrative and financial expenses.

Since 2015 China has also opened up to this possibility and improved the general conditions to facilitate the import of used machines. Since then, it has been possible to import machines after a CCIC pre-shipment inspection for 15 categories of machines and systems. Customs tariff numbers can be used to check whether it is possible to import a used machine with a pre-shipment inspection and, if so, what the conditions are.

The business outlook for used machine sellers remains good. Recently, demand in China also rose due to the recovery in the construction industry, but also because no professional used machine trade has yet been able to establish itself.

If you would also like to export a used machine to China, you will find information on pre-shipment inspection on our website.

Write us an Email or call us at +49-69-2713 769 261 for Europe and +1-773-654-2673 for America. We will gladly support you.